General Manager Vard Design

Vard Design AS

Ålesund

email hidden; JavaScript is required

At VARD, we excel in creating custom ship designs that meet the unique needs of our customers. Karl Randle, our principal naval architect, and hydrodynamics expert, underscores the significance of hull optimization, which necessitates a sophisticated interplay of professional expertise, advanced technological resources, and a commitment to precision.

06. May 2024

We’ve invested in top-tier talents and cutting-edge technology, including tools, raw computing power and automation, to rapidly develop hull designs from scratch to be ready for contract proposals in a matter of days.

Our hydrodynamics team, comprising of four engineers with specialized skills in hull design, programming, data processing, and computational fluid dynamics, collaborates closely with the stability, weight, and seakeeping teams. As shipbuilders, we are involved throughout the product’s lifecycle, from preliminary design specifications to the final sea trials. This guarantees compliance with all contractual and statutory requirements.

We collaborate with customers to capture the vessel’s operational profile and design features. We iteratively develop the hull design starting with the best hull forms in our database. Considering environmental responsibilities and by integrating new technologies, we analyze resistance, seakeeping, and stability. Through this work, we are achieving up to 30% less resistance compared to a decade ago. Our close collaborations with suppliers ensure fast support and optimal propulsion solutions, not only for transit performance but also in station keeping.

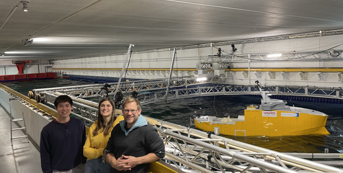

A vessel is rarely in calm water, there are design choices which can make vessels comfortable, safe and functional. With our dedicated experience and competence we optimize with a broad perspective in mind. Aspects such as the load conditions, roll reduction configurations, performance in waves, slamming and design of appendices are all taken into consideration during the optimization process to ensure the vessels performance. We can also conduct more specialized analyses, such as bubble sweep downs, roll decay tests and moon pool damping zone design.

We utilize CAESES for creating parametric hull models and incorporate leading software codes such as StarCCM+, Lemma NiceFlow, Shipflow, and ShipX. This enables us to determine the most efficient hull candidates from unlimited numbers of potential hull forms generated by our parametric tool and reduce drag in both calm water and real-world conditions with waves and wind.

We thoughtfully design appendages, acknowledging their substantial effect on resistance, which can account for up to 40% of the total ship resistance. Depending on vessel type, you may have to add many different appendages. Some have small impact on the resistance, such as a bilge keel, other can be profound, Such as the tunnel thrusters. Some may even reduce the vessel motions and resistance in wave, like bow foils or stern foils. We have spent time to develop and continue to add features to our design templates and validate our complex CFD calculations at each model test we attend. It is a continual process of discovery and verification. We do not optimize only for bare hull, but we also optimize the overall performance of the vessel.

We see owners wanting to improve their current fleet. We can offer services to repurpose or improve existing vessels, providing cost-effective fuel savings according to their operational profile.

In summary, our focus on hull optimization involves making informed decisions to deliver exceptional performance, comfort, and stability, satisfying our clients’ demands. It is a complex endeavor, but the gratification of seeing our integrated efforts come to fruition is unparalleled.

Our innovative new hull series have reduced required power by up to 40% for the same displacement vessels in a decade ago, leading to substantial fuel savings and emission reductions without compromising the cargo carrying capacity.

We’re deeply involved in R&D collaborations like the Sea Zero project with Hurtigruten. Our connection to Fincantieri, our owner, provides us access to a top-tier research ecosystem, such as the Netherlands’ Corporate Research Ships (CRS) consortium.

Fill out the form to receive more in depth content on how we work on hull optimization.

Kjell Morten Urke

General Manager Vard Design

Vard Design AS

Ålesund

email hidden; JavaScript is required

Jørn Andre Drabløs

Manager Hydro & Stability Department

email hidden; JavaScript is required