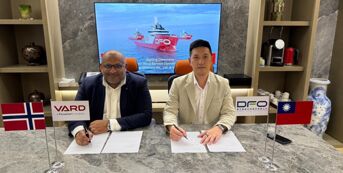

VARD signs contract for one Commissioning Service Operation Vessel

We are pleased to announce that we have signed a new contract with Taiwanese based Dong Fang Offshore for the design and construction of one Commissioning Service Operation Vessel (CSOV), a sister vessel to the two vessels VARD contracted with DFO in May 2024. This new contract is a declaration of an option in the contract DFO signed in April 2025 for one Offshore Subsea Construction vessel (OSCV).

04. May 2025

Designed for the future

After sealing the contract for two CSOVs in May 2024, Taiwanese Dong Fang Offshore (DFO) is adding a third vessel of the same design. The VARD 4 39 design was a new design from VARD developed in collaboration between DFO and VARD. The design gives a highly versatile all-round platform for sustainable windfarm support operations both as a service vessel for the wind farms and for the building and installation phase. Upon delivery, the CSOV will commence a minimum 15-year service contract for an undisclosed wind farm customer in Taiwan.

The CSOV has been developed with large design flexibility to accommodate future operational demands. The design has focus on low environmental footprint with efficient machinery and propulsion set-up for high station keeping capabilities, improved workability, and operational reliability, and a hull shape that supports the fuel efficient CSOV operation. The vessel is further prepared with a large external deck for future integration of a modular power and fiber optic cable lay and repair spread.

The third CSOV

The design includes a full electrical equipment package as part of a forward-leaning strategy in environmentally friendly design, allowing for the delivery of enhanced reliable operations onboard the ship. This includes a powerful battery package, crane and W2W gangway system. The CSOV is also prepared for future fuels.

The vessel has an aggregated hotel capacity of 120 people, whereof 90 is allocated in large single cabins. Operational centers such as offices, briefing rooms, conference room and dayrooms have been designed to meet a high standard in the market.

- We are delighted to return to VARD for the construction of the third CSOV is in our series of high performing CSOVs for the Taiwanese market, continuing the strong teamwork and momentum together with the team in Vard Vung Tau. The vessel design has been developed to specifically address the many unique challenges operating offshore Taiwan, and it is humbling to see another customer place their trust in DFO to deliver long term O&M services, on a solution that we have developed together with VARD. This order marks the third O&M service contract for an CSOV that DFO has been awarded in Taiwan, continuing the DFO strategy of building ships against high quality contracts with long-term, forward-thinking customers, and cementing DFO’s place as the O&M service provider of choice within Taiwan, says Polin Chen, CEO of DFO.

VARD a total provider

VARD is a total provider on the vessel. Through our integrated value chain, Vard Group delivers the design, builds, outfits, integrate and commission the ship for DFO.

- The new vessel will have Vard Electro’s SeaQ Integrated Bridge installed, - a bridge solution with an intuitive user interface designed for safer and more efficient operations with the operator in focus. The SeaQ Integrated Bridge is a digital enabler and serve as an interface to all operational data. For hybrid operations, the vessel is equipped with a fully integrated SeaQ Power package, designed to minimise emissions and maximise the operational window. Combined with the SeaQ Integrated Automation System (IAS), Power Management System, and Energy Management System, the newbuild gains complete control and overview of its power systems.

- Vard Interiors provides cutting-edge interior solutions and sustainable HVAC R and piping systems, with a strong emphasis on superior craftsmanship and energy efficiency. The aim is to create comfortable and functional living and working environments onboard the vessel, where both comfort and environmental considerations take center stage.

- VARD’s subsidiary Seaonics supports the project with delivery of a fully electric lift and handling system. The delivery includes a fully specked Electric Controlled Motion Compensated (ECMC) 30-meter walk-to-work gangway featuring a 3-ton 3D compensated crane and personnel elevator. For efficient cargo handling Seaonics will supply the ECMC 7-ton 3D compensated crane. The delivery includes Seaonics’ videowall solution with operator centric focus for enhanced situational awareness.

Shows VARD’s strength as an integrated shipbuilder

We are proud that DFO already chose to return to VARD for one more vessel of similar design to the two CSOVs VARD is constructing, and the OSCV contracted in April. This new contract truly shows VARD’s strength as an integrated shipbuilder, and the trust we have in the market regarding our ability to deliver on time and budget.

One of VARD's advantages is our close collaboration with our customers to tailor-make vessels based on the customer's needs and requirements, and this vessel has been developed in a fruitful process with DFO. We are looking forward to continuing our partnership with DFO in the years to come. Together we will find sustainable solutions for the offshore energy industry, says Cathrine Kristiseter Marti, CEO of Vard Group.

Trusted partner

Roger Sandnes is SVP for Sales in VARD and has been responsible for the commercial part of the contract:

VARD is very happy to see Dong Fang Offshore return for another new build. In VARD we look forward to continuing working with a trusted partner and delivering another high standard vessel for the energy market.

The vessel will be built, outfitted, commissioned, and delivered from Vard Vung Tau in Q1 2028.

Overall technical information

- Length of approx. 102.7 meters and a beam of 19.5 meters.

- Fully electric crane and walk-to-work system.

- SeaQ Integrated Bridge, Power package and Automation System.

- High seakeeping capabilities with two off eVSP 32 units and enhanced bow thruster capacities.

- Energy Storage System 1,240kWh for hybrid propulsion and fuel-efficient operation.

- Shore connection capabilities.

- Heat Recovery System and innovative HVAC system technologies for reduced environmental footprint during operation.

- Accommodation for 120 people on board; High standard crew and client facilities.

- Arranged with dedicated spaces for future technologies such as increased battery packages and possibilities for alternative fuels.

- Approx. 700 m2 Open deck for container storage and future installation of mobilizational deck equipment.

- Large warehouse facilities for enhanced flexibility in cargo storage and adjacent operational facilities for safe and efficient service operations.